Company Policy: WHTHOUS "What separates us is what we don't have"

The BMX DIY ethos is overflowing to the max out in the Rockies...

25 Nov 2019

"After 5 years of dealing with a back injury on and off. I knew from the start of working on this article that I wanted to get a riding photo for myself. Thanks to my friend John for setting the ramp up and snapping the pic." -Benjamin Smith

Interview by Rob Dolecki; photos by John Campbell, Josh Favrow and Benjamin Smith.

Comin' at ya straight from the Montana Rocky Mountains in the U.S. is a newer brand named WHTHOUS (pronounced White House). The DIY ethos is overflowing to the max out of Benjamin Smith's house, with some quality offerings as a result. Read on to learn more about the triumphs and tribulations of running WHTHOUS with the man behind it.

Logan Ostrom makes the best of long Montana winters with a Ruben ride on his indoor mini.

Explain the beginnings of WHTHOUS, why it started and how it got to where it is.

Initially the idea came about bouncing ideas back and forth with Ricky Lopez, who lived in Montana at the time and we were riding a lot together then. At first it was to just create clothing for BMX. And that’s what it started out as, but a bit more in depth. I wanted to create some nice quality cut and sew clothing and expand into different pieces. Turns out that was incredibly expensive for what you get out of it, a shirt… my interest started to shift towards hard goods and the process of how they were made.

What’s the philosophy behind WHTHOUS?

This question is tough, and its something I tend to ask myself from time to time. “Why am I doing this?” I have concluded it seems to change over time. Each year I grow older, and my outlook on BMX and life in general tends to change, and in turn the brand takes a similar shift and change.

We are now making the parts and frames how we want, with the resources we have. All funded by ourselves.

Who aside from yourself, makes things happen on a daily basis?

Ryan Ogawa is our main sales rep. He handles the majority of our dealer sales. Contacting local bike shops throughout the US. He has contributed a ton towards his local BMX scene in Fresno, and continues to shoot amazing photos in and outside of BMX. Check out his work. Both Ryan and I work day jobs at bike shops, so our time is split between that and WHTHOUS.

Who’s on the team?

At this point for us, I am helping out my friends that I have met throughout the years of riding BMX. Having the normal Pro/am/flow team format doesn’t currently work for us. Due to the size of the brand and our shoestring budget, I have felt it is hard to properly support riders with funds or a travel budget.

Here is the list of guys who are apart of WHTHOUS: Logan Ostrom, Andrew Riley, Vince Kroff, and Julian Jamerson.

What are the best and worst parts about running the company?

I handle a lot of different facets of the brand, so its refreshing to work on different parts throughout the week, or even the same day. Machining bar ends for a production run, or building jigs for future frame building can take up part of the day. Office work and media/marketing can take up the evening or other parts of the day. The downside is finding enough time to handle all of this. I still work a full-time job as a bike mechanic at a local shop. Any extra time I have usually have is focused toward WHTHOUS. It can get stressful when my progress isn’t keeping up with the expectations I have in my head. This is something I struggle with and am working on.

" The downside is finding enough time to handle all of this. I still work a full-time job as a bike mechanic at a local shop."

of 5

Why did you decide to avoid the Taiwan route, and make most hard goods in the U.S.?

I enjoy the close contact with FBM, and over time have grown to really respect those guys. John Corts, John Lee, and Mike Erb have helped me with setting the ground work on how the to create production runs of frames and parts. They have showed me how supportive people are in BMX, and a willingness to help each other out.

We haven’t completely avoided using Taiwan for production, as some parts on a BMX bike just aren’t possible to make here in the states. I want to build as many things I can in the our machine shop and the US, but still use Taiwan for the things we can’t produce here.

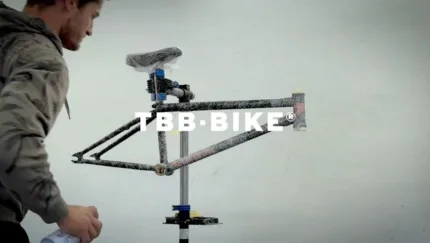

What is the motivation, and what are some of the challenges starting to produce BMX frames in-house in the U.S. in 2019?

Setting out to build frames yourself on a small production level is not easy. I have been buying machining equipment and tooling up for about three years. Finding old machining equipment across the state of Montana and figuring out the logistics of moving it to the shop is a journey in itself. Along with that, you have to make most of your tools and jigs to build each part of the frame. Lately, it has been more about building the jigs and fixtures then the actual frames. My motivation comes from taking on each of these steps, and getting closer to this goal I have set for myself and the brand.

What would you say separates WHTHOUS from other companies in BMX?

I would say it’s what we don’t have. This is run from my house, with the machine shop out back. There is no massive warehouse, just some guys who are into bikes. It’s not a big operation, but we are still offering quality parts and frames that are available for wholesale to bike shops. This has been hard to do starting out for us, we could have easily sold only direct. But it is important to offer the products to local bike shops across the country.

What new products are being released next?

We are currently working on a new frame prototype that will be produced in our shop. On the parts side, we will be debuting our seat and seat post this coming Summer of 2020. They have been on bikes being tested for a while, and I am really happy with how they turned out. This seat is just clean and simple with a slim design.

Where do you want to see the company in five years?

I hope we are producing frames for riders in-house, still making new products, and overall contributing to BMX culture.

How can people find out more about WHTHOUS?

With the heavy use of social media now, you can check us out on Instagram and facebook (@whthous) for updates of what we are doing. Also keep an eye on our website www.whthous.com where we will be releasing some new original content on a regular basis soon.

For questions about our parts, or where to buy, I recommend going to your local bike shop. They can help answer questions about our parts, prices and availability. Even if you aren’t looking for something we offer, talk to the guys in the shop and see what they suggest. A local bike shop is the backbone to that area’s BMX scene.

Is there anything you'd like to add?

I would like to thank some people who have helped and supported WHTHOUS along the way: all the Montana BMX riders; FBM machine shop guys Mike Erb, John Lee, and John Corts; Ricky Lopez, John Campbell, Chris Stevenson, Mike Brennan, Ryan Ogawa, Jesse Garcia, Kaleb Oldeni, Aaron Huff, Brad Simms, Devon Denham, Gregory Moliterno, Chris Moeller, Jason Ball, My parents, Logan Ostrom, Julian Jamerson, Andrew Riley, Vince Kroff, any locals who helped move machining equipment; and to all the shops and riders who have purchased any WHTHOUS products over the years, THANK YOU.

"This has been hard to do starting out for us, we could have easily sold only direct. But it is important to offer the products to local bike shops across the country."

I don’t know what Andrew Riley likes more. Snapping crisp tabletops, or snacking on crispy corn dogs.

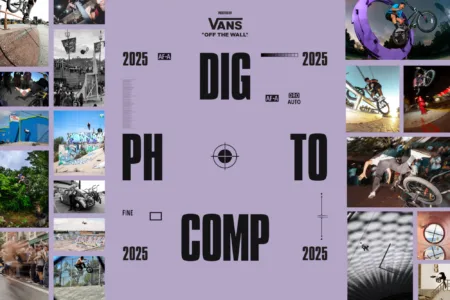

WHTHOUS are OFFICIAL DIG PARTNERS

Previous

Lookbook: Mankind Apparel - Winter 2019

Fresh Threads For The Winter Months

Next

PRODUCT DROP: CULT CREW - NEW WINTER GOODS

Yet more of the good stuff...

Related Content